Sterile ReNu SU Technology cartridge

Plug and play ReNu SU (single-use) cartridge assemblies, provided with aseptic connectors and sterility assurance claim.

Pumpheads

Quantum is an innovative bioprocessing pump providing a step-change in pump technology. Enabling higher downstream process yields throughout the pressure range, Quantum exceeds the performance of any other bioprocessing pump available.

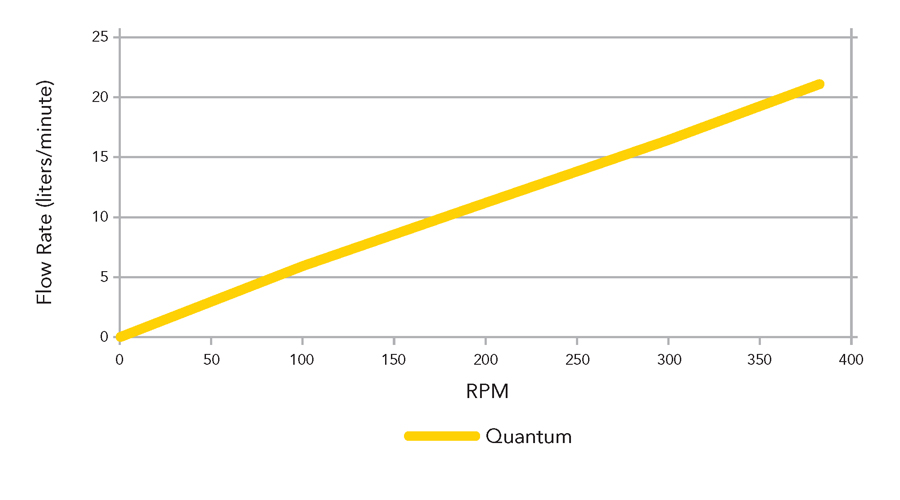

Quantum is specifically designed for tangential flow filtration (TFF), virus filtration (VF), and high-performance liquid chromatography (HPLC) applications. Quantum delivers flow linearity throughout the 3 bar single-use processing pressure range up to 20 L/min, leading the market with virtually no pulsation 0.12 bar pressure stability. 4,000:1 control ratio enables sustained transmembrane pressure (TMP) in micro and ultrafiltration via servo valves. Limited to 200:1 control ratio, Quantum also helps to overcome challenges in HPLC gradient work.

Quantum exhibits half the shear of diaphragm pumps and accurate flow at set speed through the life of the patented ReNu SU (single-use) Technology cartridge means auxiliary flow monitoring is no longer required.

Plug and play with our ReNu SU (single-use) Technology cartridge assemblies, provided with aseptic connectors and sterility assurance claim.

The patented ReNu SU Technology cartridge is simple to install, enabling its aseptic fluid paths to be positioned quickly and accurately ready for use.

| Min. flow rate | 5.33 ml/min |

| Max. flow rate | 20 L/min |

| Max. operating pressure | 3 bar |

| Max. operating pressure | 43.5 psi |

| Speed control ratio | 4000:1 |

| Operating temperature range | 5 °C to 30 °C |

| Operating temperature range | 41 °F to 86 °F |

| Control types | Remote Analogue/Digital |

| Standards | CE, cETLus, IEC 61010-1 |

| Drive ingress protection | IP66, NEMA 12/13 |

| Drive power supply | 100 V to 120 V/200 V to 240 V 1ph 50/60 Hz 250 VA |

Technical Summary table lists features available within the range. See ‘Specifications’ tab for model specific information.

| Quantum 600 | |

|---|---|

| Max. operating pressure | 3 bar (43.5 psi) |

| Speed control ratio | 4000:1 |

| Operating speed range | 0.1 rpm to 400 rpm |

| Operating temperature | 5 °C to 30 °C (41 °F to 86 °F) |

| Fluid temperature | 5 °C to 37 °C (41 °F to 98 °F) |

| Weight | 38 kg (83.8 lbs) |

| Inlet/outlet Connections | 3 x M12 chassis male 8-way, M12 chassis female 8-way |

| Control types | Remote Analogue/Digital |

| Control options | U |

| Standards | CE, cETLus, IEC 61010-1 |

| Drive ingress protection | IP66, NEMA 12/13 |

| Humidity | (Non-condensing) 80 % up to 31 °C (88 °F) decreasing linearly to 50 % at 40 °C (104 °F) |

| Noise | <70dB(A) at 1m |

| Max. altitude | 2000 m (6562 ft) |

| Drive power supply | 100 V to 120 V/200 V to 240 V 1ph 50/60 Hz 250 VA |

| Drive casework | Anodised aluminium, Silicone |

| Keypad/HMI | Polyester |

| Seals | Silicone |

| Pump drives | Universal |

|---|---|

| Manual control | |

| Intuitive keypad and colour display | ✔ |

| Choice of flow rate or speed display | ✔ |

| Full calibration with choice of flow units | ✔ |

| Remote control | |

| Configurable Start/Stop, leak detector input (via contact closure or 5V TTL or 24V industrial logic) | ✔ |

| Direction change and auto/manual toggle input (via contact closure or 5V TTL or 24V industrial logic) | ✔ |

| Remote operation of MemoDose (foot/hand-switch or logic input) | ✔ |

| Four configurable digital status outputs through 24V, 30W relays | ✔ |

| Analogue speed control | |

| Fully configurable inputs; 0-10V or 4-20mA | ✔ |

| Analogue outputs; 0-10V, 4-20mA | ✔ |

| Tacho frequency output; 0 to 1067 Hz, 0 to 400RPM | ✔ |

| Security | |

| 3-level Security PIN lock | ✔ |

ReNu SU Technology and its raw materials have been tested under a range of pharmacopoeial and non-pharmacopoeial standards. These include:

Additional testing carried out includes extractables testing. For a summary of the validation/qualification testing that has been carried out on ReNu Su Technology, please view the summary guide.

The full validation guide including additional information regarding test methods and actual test reports.

ReNu SU Technology, its raw materials and manufacturing process meets a number of regulatory compliance legislations. Specific statements relating to these compliances are available in the ReNu SU Technology compliance guide, which can be requested below.

Quantum bioprocessing pump validation summary guide

Validation summary guide PDF - 367kbTraditionally, peristaltic pumps have been the pump of choice in low pressure upstream processes including fermentation feed and media transfer. The gentle peristaltic pumping action guarantees low shear, high accuracy and zero cross contamination to uphold cell viability and corresponding high cell densities.

With this knowledge in mind, Watson-Marlow Fluid Technology Solutions designed and developed Quantum to redefine the use of peristaltic pump technology specifically for downstream bioprocessing.

By adding Quantum’s unique and revolutionary capabilities to the established peristaltic pumping principle—matched with ReNu SU Technology—Quantum is clearly the most logical choice for downstream bioprocessing.

The revolutionary performance provided by Quantum extends the frontiers of peristaltic technology, delivering up to 3 bar constant pressure with only trace pulsation of 0.12 bar throughout the flow range.

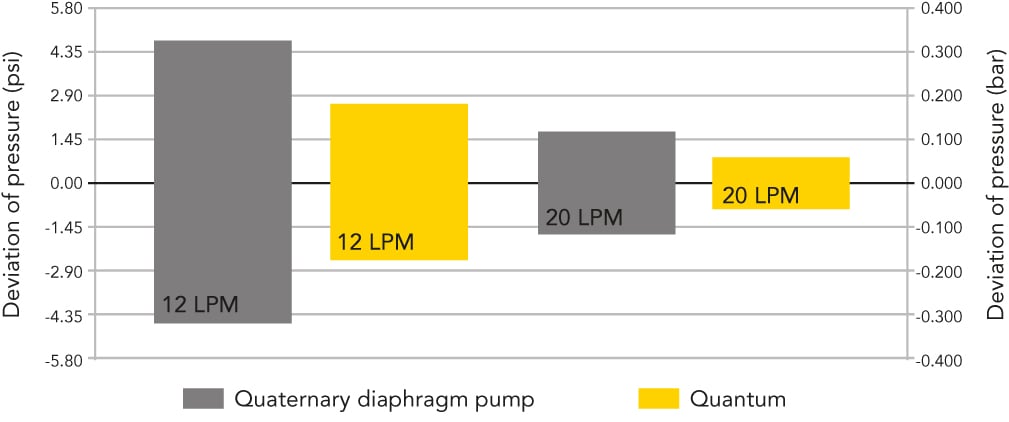

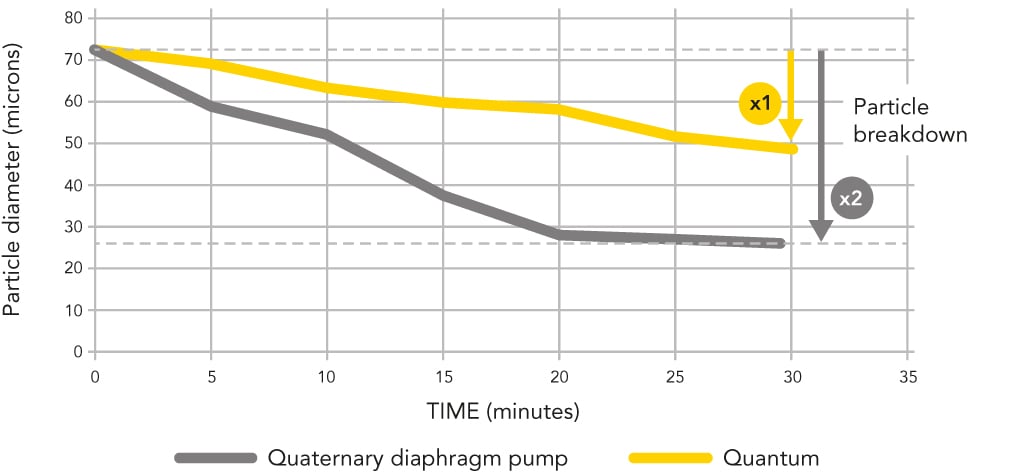

Quantum matched with its patented ReNu SU Technology cartridge delivers ultra-low shear and accuracy at set speed throughout the cartridge life. The independent test data demonstrates how Quantum delivers low shear and higher process yields by comparing the mean diameter of fragile oil based emulsion particles as they pass through a pump. The particle breakdown is twice as much with the quaternary pump (grey line) as with Quantum (yellow line). Tests were conducted at 12 L/min and 14.5 psi (1 bar) pressure.

The data presented in the above two graphs was provided by an independent third-party source

Quantum delivers flow linearity throughout the pressure range. With a 4,000:1 control ratio, operators can sustain constant transmembrane pressure in micro/ultrafiltration.

Plug and play with our ReNu SU (single-use) Technology cartridge assemblies, provided with aseptic connectors and sterility assurance claim.

Sterile ReNu SU Technology cartridge assemblies guarantee quick and secure fluid path connections. These products are released based on a VDmax25 study as detailed by ANSI/AAMI/ISO 11137 guidelines, to provide a sterility assurance level (SAL) of 10-6 when irradiated to a minimum of 25 kGY.

Standard ReNu SU cartridge assemblies include a range of aseptic connectors which enable sterile connections to be made in controlled non-classified spaces.

Quantum successfully combines application specific pump capabilities with single-use fluid path components such as the ground breaking ReNu SU Technology cartridge, the popular BioPure range of barbs, clamps, gaskets and high pressure braided hose. For the first time, this integrated approach allows a considerable reduction in cost and time of pump validation prior to being specified into single-use systems (SUS).

ReNu SU Technology cartridges are fully manufactured in ISO Class 7 cleanrooms and are suitable for gamma irradiation at up to 50kGy. ReNu SU Technology cartridges are supplied with an industry-leading validation guide. The guide includes a comprehensive set of biocompatibility data with material tests such as USP88, Class VI (in vivo) and USP87 (in vitro). Detailed extractable testing with a range of solvents in line with BPOG and BPSA guidelines has also been undertaken. The validation guide supports your validation process, reducing your overall time to market.

The secure and consistent positioning of the ReNu SU Technology cartridge in the pumphead—clamped firmly in place at its manifolds—guarantees a secure connection every time. Additionally each cartridge is supplied with a quick change kit comprising of clamps, gaskets and end caps all designed to keep the time it takes to replace a cartridge to a minimum.

Connection kits are also available consisting of braid reinforced silicone hose configured to customers’ requirements with BioBarb fittings. All components are manufactured in ISO Class 7 cleanrooms.

The synergy between peristaltic pumps and single-use pump systems cannot be overstated. The ReNu SU Technology cartridge slides effortlessly into position allowing for a change of fluid path in minutes whilst eliminating alignment errors.

| Description | Partcode |

|---|---|

| ReNu SU 600 20/3P | 33-1061-000001 |

| ReNu SU CONNECTION KIT, BRAIDED PLATINUM-CURED SILICONE HOSE, 3/4” TC E/E, 0.5 MTR | 33-1069-000001 |

| ReNu SU CONNECTION KIT, BRAIDED PLATINUM-CURED SILICONE HOSE, 3/4” TC E/E, 1 MTR | 33-1069-000002 |

| ReNu SU CONNECTION KIT, BRAIDED PLATINUM-CURED SILICONE HOSE, 3/4” TC E/E, 3 MTR | 33-1069-000003 |

Plug and play ReNu SU (single-use) cartridge assemblies, provided with aseptic connectors and sterility assurance claim.

Pumpheads

Simple and efficient one handed, tool free clamping solution for all connector types. Unique true tamper evident cover.

Fluid path - connectors

Designed in accordance with ASME-BPE standards. USP Class VI compliant and animal derived component free (ADCF).

Fluid path - gaskets

Flow rates to 190 ml/min (3.04 USGPH) and pressures up to 2 bar (30 psi). Speed control up to 10,000:1.

Pumps - cased pumps

Flow rates from 2 μl/min to 2,000 ml/min and pressures up to 2 bar (30 psi). Single or multi channel.

Pumps - cased pumps

Flow rates to 3.5 L/min (55 USGPH) and pressures up to 7 bar (100 psi). Precise 2,200:1 speed control range.

Pumps - cased pumps

Flow rates to 18 L/min (4.76 USGPM) and pressures up to 4 bar (60 psi). Precise 2,650:1 speed control range.

Pumps - cased pumps

Flow rates to 33 L/min (8.8 USGPM) and pressures up to 2 bar (30 psi). Precise 3,600:1 speed control range.

Pumps - cased pumps

Flow rates to 2,000 ml/min (31.7 USGPH) and pressures up to 9 bar (130 psi).

Pumps - cased pumps

To order a product or ask a question